- home

- aboutkeyboard_arrow_down

- productskeyboard_arrow_down

- application

- honor

- newskeyboard_arrow_down

- contact

【 Valve Application 】

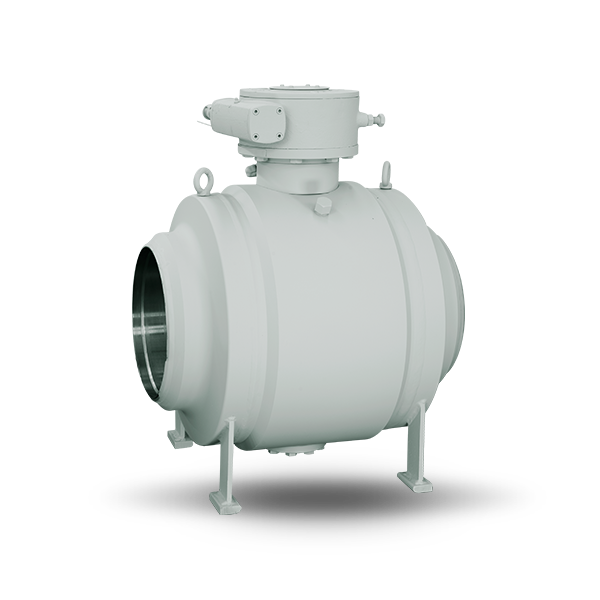

The fully welded ball valve is made by forging and welding plates. Its weight is about 10 to 20% lighter than that of the bolted structure, and the valve volume is also smaller. Meanwhile, it also reduces the external leakage points of the valve and improves the reliability of the valve in use. Different drive methods can be selected to meet the control requirements of valves in different industries and mines. Fully welded ball valves are widely used in long-distance natural gas pipelines and buried pipelines with severe corrosion such as hydrogen sulfide, and have a relatively long service life.

【 Basic Characteristics 】

As the valve seat is composed of a carbonized Teflon sealing ring and a disc spring, it has a strong adaptability to changes in pressure and temperature, and will not cause any slippage within the marked pressure and temperature range.

2. The processing of the sphere is tracked and inspected by advanced computer detectors, so the processing accuracy of the sphere is high.

3. As the valve body material is the same as that of the pipeline, there will be no uneven stress, nor will it deform due to earthquakes or vehicles passing over the ground. The pipeline is resistant to aging.

4. The sealing ring body is made of RPTFE material with 25%Carbon content, ensuring complete no leakage.

5. The directly buried welded ball valve can be directly buried underground without the need to build large valve Wells. Only small shallow Wells need to be set up on the ground, which greatly saves construction costs and project time.

6. The fully welded ball valve can adjust the length of the valve body and the height of the valve stem according to the construction and design requirements of the pipeline.

7. The processing accuracy of the sphere is extremely precise, the operation is convenient, and there is no adverse interference.

Under the condition of ensuring the normal operation and use of the fully welded ball valve, its service life is over 15 years.

Design standard: API 6D

Structural length: ASME B16.10,API 6D

Connection end standards: ASME B16.25,ASME B16.5

Inspection standards: API 6D,API 598

Size: 2" to 56"(DN25 to DN1400)

Nominal pressure: ASME CLASS 150-1500 (PN16 - PN250)

Valve body materials: A105, F304, F316, etc.

Sphere materials: A105+ENP, F304, F316, etc.

Valve stem materials: 410SS,17-4PH, F51, etc.

Valve seat materials: PTFE, PEEK, NYLON

Connection terminals: RF, RTJ, BW

Operation: Handle, gear, electric, pneumatic, hydraulic